Welcome To Chemion AG

Redispersible Polymer Powders(RDP)

Redispersible Polymer Powders (RDP)

Applications for RDPs include the formulation of construction materials such as tile adhesives, grouts, finishing plasters, troweling

compounds, thin set mortars, and sealing slurries. The amount of RDPs added to cements and plaster is about 2-10 percent, depending

on the improvement of strength, impact resistance, adhesion, and water resistance required of the compound.

The advantages of incorporating RDPs in dry-mix formulations include improvements in workability and water retention, plasticity,

dispersion, and freeze stability. The resins are soft and flexible because of their relatively high ethylene contents. As a modifier, RDPs

improve flex strength, crack resistance, adhesion, abrasion and impact resistance, and water repellency

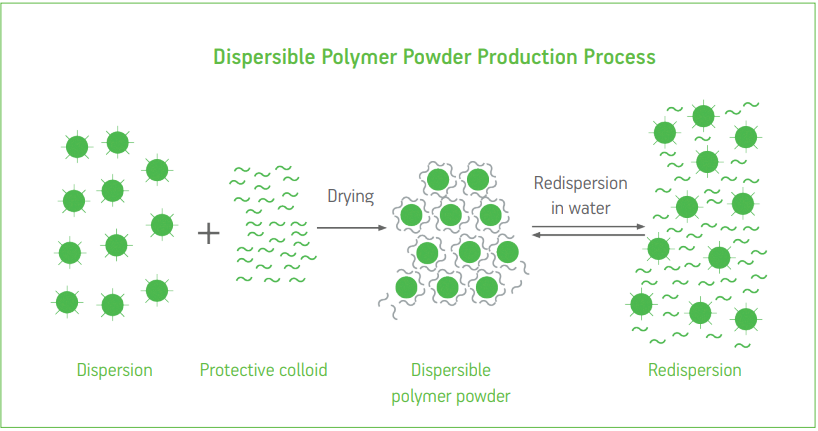

RDP is a free-flowing, white powder obtained by spray drying of an aqueous vinyl acetate-ethylene copolymer dispersion. Redispersible

polymer powders are polymer emulsions which have been converted by spray drying (atomizing the aqueous polymer dispersions

in a stream of hot air) to free flowing powders. When blended with water, these powders redisperse back into liquid emulsions with

essentially identical properties to the original emulsions.

- Cement based wall putties

- Wallpaper adhesives

- Cement based tile adhesives

- Crack fillers

- Adhesion mortars

- Gypsum joint fillers

- Repair mortars

- Cement Renders

- Has excellent water-repellent and hydrophobic properties

- Improves the adhesion, flexural strength, plasticity, abrasion resistance and good workability of modified compounds

- Gives proper adhesion for external insulation and finishing system.

- Used as Self-leveling troweling compounds and flooring compounds

- Improves the workability and other important mechanical properties like tensile-, compression- and flexural strength, as well as the transversal deformation

- Provides excellent slip resistance, impact resistance and helps to reduce the formation of cracks caused by shrinkage.

Chemion AG Copyright© 2024. All right reserved